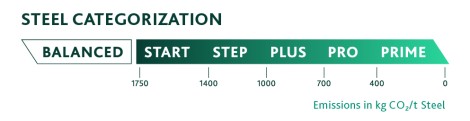

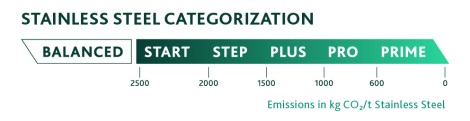

Reduce CO2 emissions with recycled steel

We work together with customers and suppliers to create closed loops and more sustainable supply chains to contribute to building a circular economy.

For existing closed loops, we collect scrap generated during the processing of our products and send it off for steel recycling. Thanks to its durability and low maintenance, steel is one of the most preferred materials the world over, be it for construction, the automotive industry or shipbuilding.

Steel can be recycled ad infinitum without impairing its quality.

The excellent material properties of steel and its recycling options reinforce our firm belief that steel is not the problem, but part of the solution.