Those operating with inefficient workflows in their analogue business will find themselves struggling with the same problems even after digitalisation. As a specialist in steel and metals, Debrunner Acifer AG has therefore been investing for years in the digitisation of its processes.

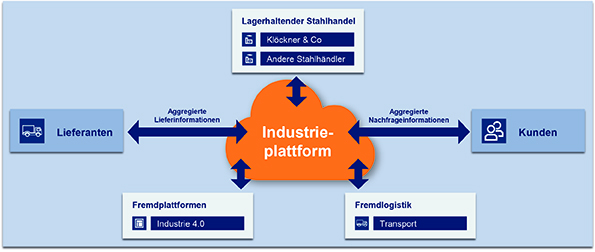

An important part of Debrunner Acifer‘s strategy is the automation of process chains involving suppliers and customers. The Switzerland-wide B2B company has created direct connections with suppliers, third-party vendors, E-marketplaces and customers via EDI systems, ERP systems, planning software and warehouse management systems. Customers enter orders in the ERP system or submit CAD drawings electronically, triggering an automated purchase process.

One of the ways Debrunner Acifer AG has laid the groundwork for further expanding its degree of automation is by building a new Logistics Centre for C-parts in Kölliken. Another step in process optimisation is taking place in Birsfelden – with the expansion of the country’s largest central warehouse for steel. The investment in the automated high-bay warehouse improves efficiency, increases availability and enables precise distribution.

Central database for the E-business platform

A further precondition for efficient ordering processes is the standardisation and digitisation of product data. Debrunner Acifer AG has developed a central database that enables the standardised maintenance of all data on its comprehensive range of more than 160,000 products. The information in this digital database can then be used to create publications such as print catalogues, brochures and flyers as well as to keep the E-business platform supplied with current product data.